Home > Valve > Automatic Control Valve

Rate-of-Flow Control Valves

Features

400X Rate-of-Flow Control Valves is uses for its high accuracy pilot operated flow control and is suitable for flow and pressure control of the pipeline to keep the flow preset unchanged, limit an extra-big flow at the preset value and properly lower the high pressure on the upstream, the flow at the downstream will not be affected by the pressure changing of the main valve at the upstream. It changes the principle of a throttle valve to reduce the basin area purely mechanically or by way of using orifices and utilizing the related pilot valve to reduce the energy loss during throttling to the utmost extent. And it features by sensitive control, safety, reliability, easy debugging and long duration.

400X Rate-of-Flow Control Valves is a kind of multifunctional valve, using advanced pilot method to control flow rate of fluid. It is used in the pipeline where flow rate and pressure need to keep stable and keep the flow rate stable and limit the over large flow rate to the preset flow rate in the downstream do not change. This kind of is different general throttle valve that reduces flow area to control flow rate, it uses related pilot valve is different general throttle valve that reduce flow area to control flow rate, it uses related pilot valve to reduce energy loss when throttling. In emergency vt-400X flow control valve can shut off the fluid and avoid loss. Its sensibility is very high and it is very safe and reliable and it's life is very long and it is very easy to maintain.

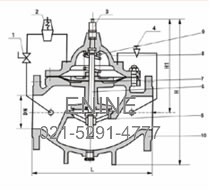

Rate-of-Flow Control Valves

1. Small Ball Valve

2. Pilot Valve

3. Flow Controller

4. Needle Valve

Technical Parameters

Nominal Pressure: 1.0, 1.6, 2.5MPa

Shell test pressure: 1.5, 2.4, 3.75MPa

Sealed test pressure : 1.1, 1.76, 2.75MPa

Suitable temperature: 80

Suitable medium: water, Sewage

Materials

| Serial No. | Part | Material |

| 1 | Little Ball Valve | |

| 2 | Pilot Valve | |

| 3 | Flow Adjustor | |

| 4 | Needle Valve | |

| 5 | Seat | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 6 | Stem | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 7 | Diaphragm | Rubber |

| 8 | Cover | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 9 | Spring | Spring Steel |

| 10 | Body | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

Dimensions

| DNmm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| L | 180 | 180 | 180 | 203 | 203 | 235 | 285 | 360 | 400 | 455 | 585 | 650 | 800 | 860 | 915 | 980 | 1075 | |

| PN10 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 390 | 440 | 500 | 565 | 615 | 670 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | |

| PN16 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 460 | 520 | 580 | 640 | 705 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | |

| PN25 | D | 105 | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | |

| H | 342 | 342 | 342 | 395 | 395 | 405 | 430 | 510 | 560 | 585 | 675 | 730 | 760 | 840 | 910 | 1030 | 1135 | |

| H1 | 247 | 247 | 247 | 278 | 278 | 298 | 313 | 350 | 365 | 420 | 450 | 470 | 490 | 526 | 570 | 610 | 665 | |

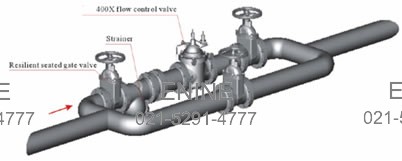

Typical Installation

- Ball Valves

- Butterfly Valves

- Cast Steel Valves

- Bellows Seal Valves

- Forged Steel Valves

- Regulate Valves

- Balance Valves

- Check Valves

- Safety Valves

- Instrumentation Ball Valves

- Resilient Seated Gate Valves

- Safety Relief Valves

- Plug Valves

- Globe Valves

- Discharge valves

- Instrument Manifolds

- Needle & Gauge Valves

- Automatic Control Valves