Home > Valve > Automatic Control Valve

Solenoid Float Control Valves

Features

Solenoid Float Control Valves is with normal open (normal close) Solenoid control equipment based on 100x Float Control Valves. So even if there is no electric power or the flow could not work, it can assure the water level is not beyond the set level and the electric float valve can preset the on/off water level to solve the problem of main valve's frequently opening/closing. This kind of valve is widely used in high building, feeding system, fire protection, at the inlet of water pool and water tower of enterprises.

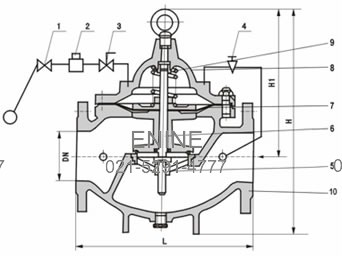

Solenoid Float Control Valves

1. Float Ball Pilot Valve

2. Solenoid Valve

3. Ball Valve

4. Needle Valve

Technical Parameters

Nominal Pressure: 1.0, 1.6, 2.5MPa

Shell test pressure: 1.5, 2.4, 3.75MPa

Sealed test pressure : 1.1, 1.76, 2.75MPa

Suitable temperature: 80

Suitable medium: water, Sewage

Materials

| Serial No. | Part | Material |

| 1 | Little Ball Valve | |

| 2 | Pilot Valve | |

| 3 | Flow Adjustor | |

| 4 | Needle Valve | |

| 5 | Seat | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 6 | Stem | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 7 | Diaphragm | Rubber |

| 8 | Cover | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 9 | Spring | Spring Steel |

| 10 | Body | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

Dimensions

| DNmm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

| L | 180 | 180 | 180 | 203 | 203 | 235 | 285 | 360 | 400 | 455 | 585 | 650 | 800 | 860 | 915 | 980 | 1075 | 1230 | 1300 | 1450 | |

| PN10 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 390 | 440 | 500 | 565 | 615 | 670 | 780 | 895 | 1010 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | |

| PN16 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 460 | 520 | 580 | 640 | 705 | 840 | 910 | 1020 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | |

| PN25 | D | 105 | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 | 955 | 1070 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | 875 | 990 | |

| H | 212 | 212 | 212 | 265 | 265 | 310 | 350 | 460 | 520 | 570 | 695 | 780 | 905 | 1025 | 1080 | 1030 | 1135 | 1270 | 1460 | 1640 | |

| H1 | 179 | 179 | 179 | 210 | 210 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 696 | 735 | 610 | 665 | 725 | 865 | 975 | |

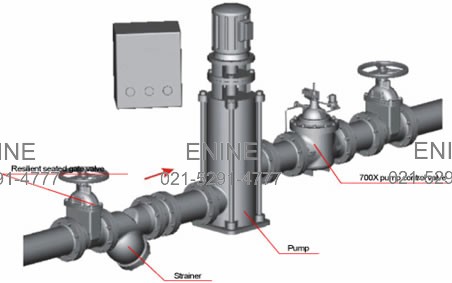

Typical Installation

- Ball Valves

- Butterfly Valves

- Cast Steel Valves

- Bellows Seal Valves

- Forged Steel Valves

- Regulate Valves

- Balance Valves

- Check Valves

- Safety Valves

- Instrumentation Ball Valves

- Resilient Seated Gate Valves

- Safety Relief Valves

- Plug Valves

- Globe Valves

- Discharge valves

- Instrument Manifolds

- Needle & Gauge Valves

- Automatic Control Valves